In modern construction, the demand for energy-efficient and environmentally sustainable building materials is higher than ever. One of the most innovative solutions in masonry is the perforated brick—a brick designed not just for structural integrity but also for superior thermal insulation. Unlike conventional solid bricks, perforated bricks have carefully designed holes or perforations that reduce their weight, improve heat resistance, and enhance overall building performance. This article explores the science behind thermal insulation in perforated bricks, examining their structure, materials, and benefits. We’ll also look at how leading manufacturers like Kailash Bricks are setting new benchmarks in sustainable construction.

1. Understanding Perforated Bricks

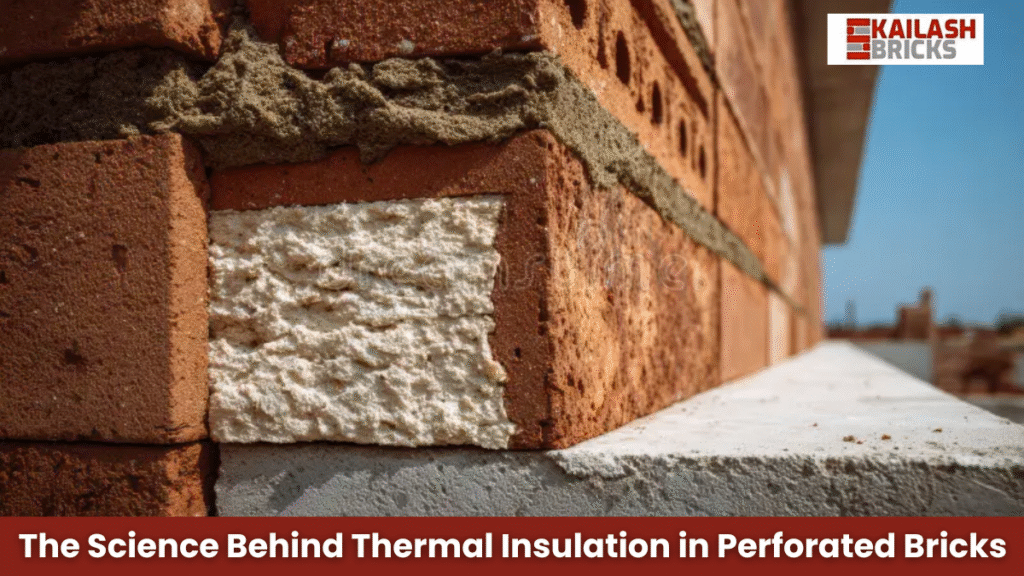

Perforated bricks are clay bricks with cylindrical or rectangular holes that pass through their thickness. These perforations typically occupy about 25–60% of the brick’s volume. The primary purpose of these perforations is twofold:

- Material Efficiency: By reducing the volume of clay needed, perforated bricks use fewer raw materials, making them more sustainable and cost-effective.

- Thermal Insulation: The air trapped in the perforations acts as a natural barrier to heat transfer, significantly improving the brick’s thermal performance.

Manufacturers such as Kailash Bricks have refined this design to achieve the perfect balance between strength and insulation, ensuring that the bricks meet modern construction demands.

2. Thermal Conductivity and the Role of Air

The effectiveness of perforated bricks lies in their ability to limit thermal conductivity. Thermal conductivity is the measure of a material’s ability to conduct heat. Solid clay has a higher thermal conductivity than air, meaning that it transfers heat more readily. By introducing perforations, the brick traps air pockets within its structure.

Air has a very low thermal conductivity—around 0.024 W/mK, compared to fired clay’s 0.6–1.0 W/mK. These trapped air pockets slow down heat transfer through the wall, keeping interiors cooler in summer and warmer in winter. This natural insulation reduces the need for artificial cooling or heating, leading to significant energy savings over time.

Kailash Bricks, known for their high-quality clay and precision manufacturing, optimize the size and distribution of perforations to maximize this insulating effect while maintaining structural strength.

3. Perforation Patterns and Their Impact

Not all perforated bricks are the same. The pattern, shape, and distribution of holes have a direct impact on thermal insulation:

- Vertical Perforations: Allow better load-bearing capacity while maintaining good insulation.

- Horizontal Perforations: Offer slightly better insulation but may be less suitable for heavy structural loads.

- Circular Holes: Common due to ease of manufacturing and balanced thermal performance.

- Rectangular or Slotted Holes: Provide enhanced airflow and sometimes better insulation characteristics.

Leading manufacturers like Kailash Bricks carefully design these perforations based on building requirements, ensuring that the brick’s geometry enhances thermal performance without compromising durability.

4. Material Composition and Firing Techniques

Thermal insulation isn’t determined by perforations alone; the material composition and firing techniques also play a crucial role. High-quality clay with low impurities results in bricks with more consistent pore structures and better insulation. Additives such as fly ash or sawdust are sometimes included to create micro-pores, further improving insulation.

Advanced kiln firing techniques, like those used by Kailash Bricks, ensure uniform firing temperatures. This results in bricks that are not only strong but also possess optimal porosity for thermal efficiency. Uniform porosity ensures that air pockets are evenly distributed, maximizing the insulating effect.

5. Energy Efficiency and Building Performance

Buildings constructed with perforated bricks demonstrate remarkable energy efficiency. According to studies, walls made with perforated bricks can reduce heat transmission by up to 30–50% compared to solid brick walls. This reduced thermal bridging translates into lower HVAC loads, reduced electricity bills, and a more comfortable indoor climate.

Builders and architects are increasingly choosing perforated bricks from trusted suppliers like Kailash Bricks, not just for their environmental benefits but also for their contribution to Green Building Rating Systems such as GRIHA and LEED. Using these bricks can help projects achieve higher sustainability scores and certifications.

6. Moisture Resistance and Breathability

An often-overlooked advantage of perforated bricks is their breathability. The perforations allow for controlled vapor permeability, which helps maintain healthy indoor humidity levels. At the same time, modern perforated bricks are engineered to resist direct water penetration, preventing moisture build-up inside walls.

Manufacturers like Kailash Bricks employ precise molding and finishing techniques to ensure that perforations do not become moisture traps. Their bricks are tested for both water absorption and vapor transmission, guaranteeing long-lasting performance even in humid climates.

7. Structural Performance and Weight Reduction

Despite their perforations, these bricks maintain excellent structural strength when manufactured correctly. The reduced weight of perforated bricks—often 20–30% lighter than solid bricks—makes them easier to handle and transport. This leads to faster construction times and lower structural loads on foundations and supporting elements.

Kailash Bricks uses state-of-the-art extrusion and firing methods to produce perforated bricks with consistent density and compressive strength. This ensures that they meet or exceed IS standards while offering superior insulation properties.

8. Environmental Impact and Sustainability

The environmental benefits of perforated bricks are significant:

- Reduced Material Use: Less clay per brick means fewer natural resources consumed.

- Lower Embodied Energy: Lighter bricks require less energy for firing and transportation.

- Improved Energy Efficiency: Buildings need less energy for cooling and heating.

- Recyclability: Perforated bricks can be recycled or reused in new construction.

With growing awareness of sustainable construction, Kailash Bricks has become a preferred choice among eco-conscious builders and architects. Their commitment to eco-friendly production methods—such as using cleaner fuels and efficient kilns—aligns with modern green building practices.

9. Practical Applications

Perforated bricks are versatile and used in various applications:

- External walls: Providing insulation while maintaining strength.

- Partition walls: Lightweight and easy to install.

- Ventilated façades: Enhancing airflow and thermal comfort.

- Architectural features: Offering aesthetic appeal with functional benefits.

Many architects source perforated bricks from Kailash Bricks for both residential and commercial projects, appreciating their balance of performance, durability, and design flexibility.

Conclusion

The science behind thermal insulation in perforated bricks lies in their intelligent design, material composition, and manufacturing precision. By incorporating air pockets within their structure, these bricks drastically reduce heat transfer, contributing to energy-efficient, comfortable, and sustainable buildings.

As the construction industry moves toward greener solutions, the role of high-quality perforated bricks becomes increasingly vital. Companies like Kailash Bricks are at the forefront of this innovation—producing bricks that not only meet structural and thermal requirements but also align with environmental goals. Whether you’re an architect designing modern energy-efficient spaces or a builder looking for reliable materials, perforated bricks offer a smart, sustainable solution for the future of construction.