Quick Links

- Home

- About Us

- Gallery

- Contact Us

Contact US

- +91-9813684413

- kailashbricks@gmail.com

- VPO Laloda, Tohana, Dist. Fatehabad, Haryana -125120

©2023. KAILASH BRICKS. All Rights Reserved.Designed By EJS WEBSERVE.

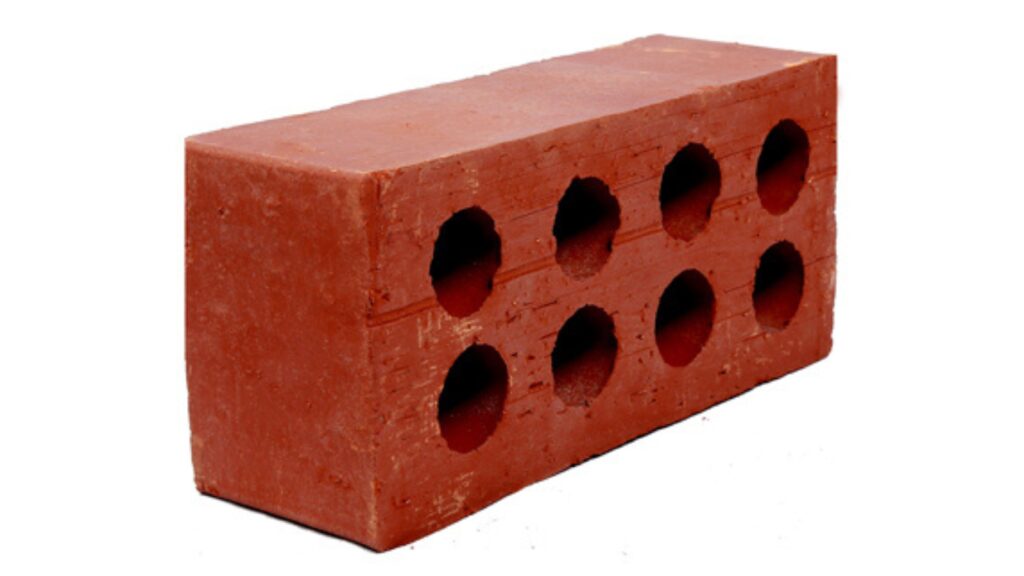

Size (in mm): 230x112x65

Compressive strength: ~370kg/cm2

Water absorption: 5-6%

These extruded bricks are used in the application of sewer manholes owning to its very less water absorption, high frost resistance, and high compressive strength

©2023. KAILASH BRICKS. All Rights Reserved.Designed By EJS WEBSERVE.